APPROACH

The movement opened a whole new level of questioning: would I use parts from other watches such as winding/setting system, escapement and gear train? Would I take measurements from movements that exist already but make the parts myself? Basing my mechanism on another would comfortably guarantee that it would be running well and minimize the risk of failure.

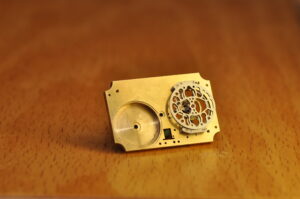

I had a bigger purpose with my project, I was intent on upgrading my own professional knowledge while making it as interesting as it gets: I decided to start from a blank page and design every part from scratch with no influence of existing movements. In this way, not only would my own influence on the final product be greater but it would grant me the possibility to fine tune critical components such as the escapement (compared to using parts designed for mass production).

As with the movement I wanted to make the case by myself as well. The prototype would be made out of 3 parts in brass.

Based on the experience on making the watch in the way that I have chosen, I will be taking a new aim as an independent watchmaker: making of watches that are truly 100 % a product of a single watchmaker’s involvement. Meaning that every single part (with the exception of the parts that are rather difficult to manufacture: jewels and springs) in a watch should be made from a raw material by myself, with the help of only traditional manual machines and hand tools. For me as a watchmaker, working in this way gives me a huge satisfaction and I can take pride in the product that come out of my work as they are the result of my personal choices only.